Benefits of Augmented Reality (AR) for Manufacturing

Posted on May 10, 2023 3 minutes 543 words

Table of contents

In recent years, augmented reality (AR) has emerged as a groundbreaking technology that’s transforming various industries, including manufacturing. By overlaying digital information onto the physical environment, AR has the potential to enhance productivity, reduce costs, and improve safety in the manufacturing sector. In this blog post, we’ll explore the top benefits of AR technology in manufacturing and how it’s revolutionizing the industry.

Enhanced Maintenance and Repair

AR technology has the potential to streamline maintenance and repair processes by providing technicians with digital information and instructions overlaid onto the physical environment. This augmented view helps diagnose issues faster, reduce errors, and minimize downtime. For example, an AR headset could display a virtual schematic of a machine, enabling technicians to easily identify faulty components and access repair instructions.

Improved Training and Skill Development

Traditional training methods can be time-consuming and costly. However, AR technology offers a more efficient and engaging approach to employee training by simulating real-world scenarios. This immersive experience accelerates skill development, reduces learning curves, and shortens onboarding times. For instance, AR applications can guide trainees through complex assembly processes or help them learn to operate new machinery with step-by-step instructions.

Real-Time Collaboration and Remote Assistance

In today’s globalized world, teams are often spread across multiple locations. AR facilitates seamless collaboration by allowing team members to see and work on the same virtual project simultaneously. Remote assistance becomes possible through AR as well, connecting field technicians with experts to solve complex problems in real time. This technology can significantly reduce travel costs and improve knowledge sharing within an organization.

Quality Control and Inspection

AR technology can improve quality control and inspection processes by providing real-time information on product specifications, tolerances, and defects. This enhanced view enables better decision-making, reduced rework, and increased customer satisfaction. For instance, inspectors can use AR devices to compare a physical component against its digital counterpart, immediately identifying any deviations or issues.

Ergonomics and Worker Safety

Worker safety and ergonomics are essential considerations in manufacturing. AR can help enhance these aspects by providing real-time data on proper posture, lifting techniques, and safety guidelines. This technology can reduce workplace injuries and improve overall worker wellbeing by encouraging adherence to best practices and minimizing the risk of accidents.

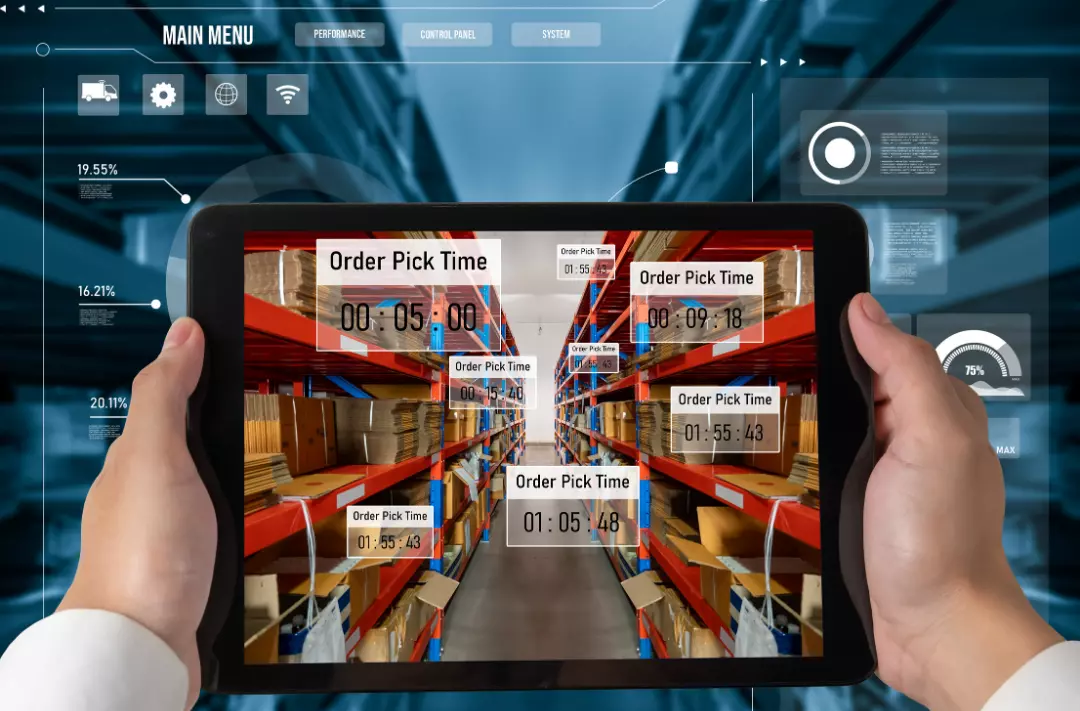

Inventory Management and Logistics

Efficient inventory management and logistics are crucial to a successful manufacturing operation. AR technology can optimize these processes by providing real-time information on stock levels, locations, and tracking. This enhanced visibility leads to reduced carrying costs, improved order fulfillment, and increased warehouse efficiency.

Streamlined Design and Prototyping

AR technology can accelerate the design and prototyping process by allowing engineers to visualize and manipulate 3D models in a real-world environment. This immersive experience enables more accurate simulations, reduces material waste, and promotes innovation. For example, engineers can overlay a virtual prototype onto a physical workspace, making it easier to identify potential issues and make necessary adjustments.

Conclusion

Augmented reality holds immense potential to revolutionize the manufacturing industry by offering numerous benefits, including improved training, enhanced maintenance and repair, real-time collaboration, better quality control, and increased worker safety. As this technology continues to advance, manufacturing organizations should stay informed and consider implementing AR solutions to stay competitive and drive innovation.